For a cutting-edge, high-tech mill specializing in producing high quality extra virgin olive oil, we have engineered a treatment system for all primary and process water.

Based on the request received to sanitize and monitor the olive washing water, we have drawnattention to the fact that disinfection with an oxidizing agent alone is not sufficient, or rather, it forces one to operate with very high concentrations and related problems; not least the possible deterioration of the fruit itself.

In our experience of water treatment for the fruit and vegetable processing industry, we have always encountered requests for sanitization only and without ever thinking of removing as much as possible from the water all those organic and inorganic elements that contribute to the increase in turbidity of the water itself.

Doing this instead allows us to use sanitizing products in reduced quantities and aimed above all at disinfecting the real recipient of this action (in this case the olive fruit).

Another important aspect, in our opinion often underestimated, is to question the physiochemical characteristics of the starting water that you intend to use in your transformation cycle, and its origin (aqueduct, surface, well, etc.).

Given this, a water treatment plant was specifically designed and took these aspects into consideration.

Water softening

An automatic water softener has been installed upstream of all the water destined for the mill to reduce hardness, thus ensuring softened water for all uses in the mill including, of course, for loading and replenishing the water in the olive washing tanks.

Due to its physiochemical characteristics, softened water has a greater cleaning power than mains water (of medium- high hardness).

Feeding the plant with softened water has in fact brought benefits to all processes, such as protecting all the utilities and various machines from encrustation phenomena, the cleaning of which is essential in the food industry.

Filtration - Control of pH, Temperature, Chlorine Dioxide and Turbidity

The olive washing section, consisting of three tanks, has been equipped with relative sand filtration systems, whose recirculation pump, in addition to feeding the filter itself, continuously sends the water to be analyzed to the main control panel that houses a multi-parameter control instrument for each tank.

The first two tanks are monitored for the pH, Temperature, and Chlorine Dioxide values, while the third, in addition to these parameters, reports the Turbidity value; this is an important index for the evaluation and effectiveness of the proposed treatment.

Based on the set-point set for the individual tank, the sanitizing product is injected using a dedicated dosing pump.

For the periodic cleaning of the filters, the water contained in the tank is not used, but rather the stored softened water.

Chlorine Dioxide Dosage

As a sanitizing product, a solution of stabilized chlorine dioxide was chosen, widely used in the food industry and in the treatment of water for drinking purposes. Unlike other oxidizing agents, its use does not cause any alteration of taste, odor or appearance and is an adjuvant in the reduction of turbidity due to its flocculating action.

In the plant in question, the set-point value set for the residual chlorine dioxide was 0.20 ppm, the regulatory limit for water intended for human consumption.

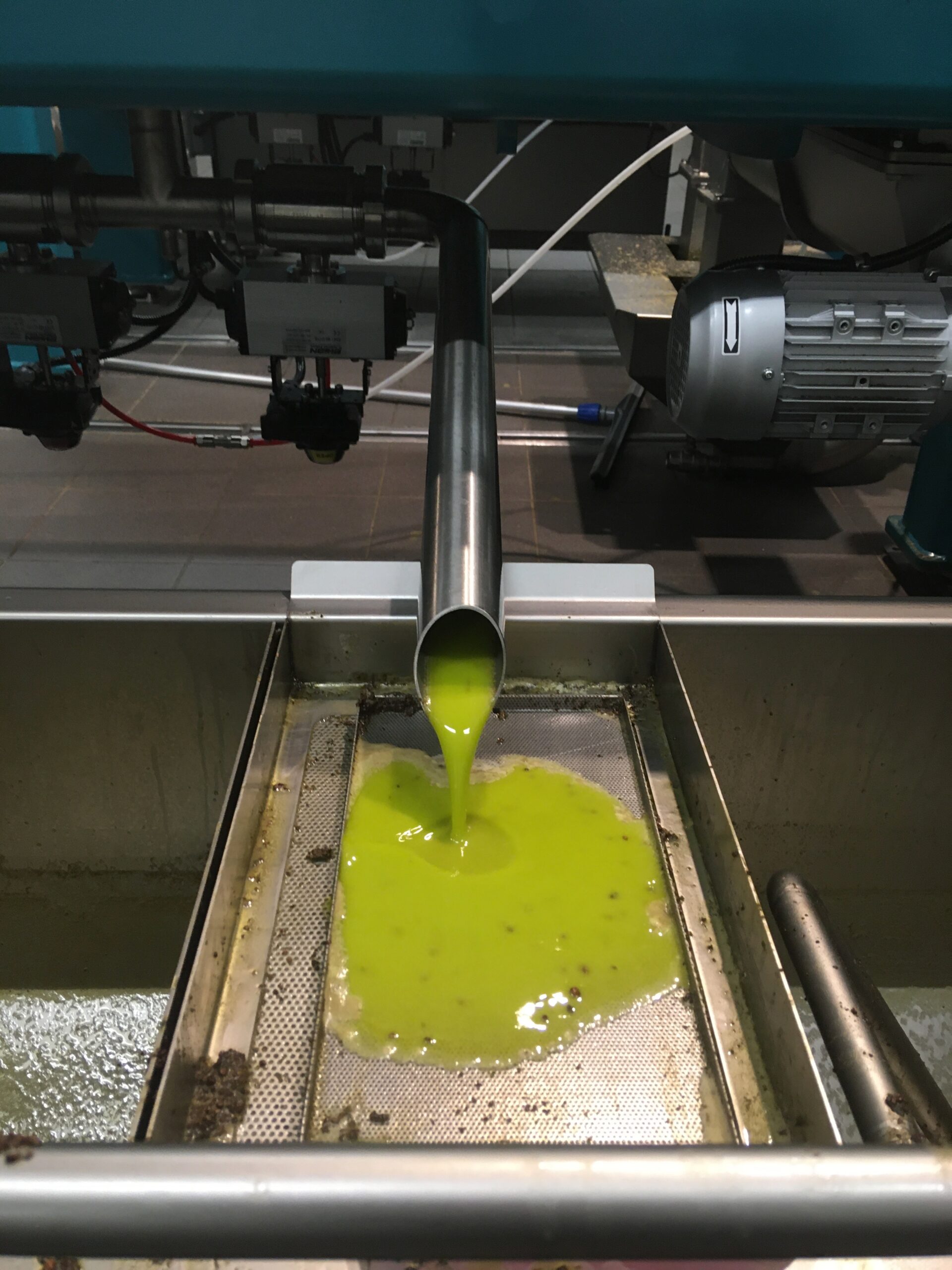

The plant created guaranteed cleaner washing water, the reduction of the bacterial load, a vehicle for fermentation, and thus sent the cleaned and sanitized olives to the next stage of transformation.

Cleaner water circulating in the tanks allowed to reduce the changes of the washing water with consequent savings and facilitated the daily cleaning operations of the tanks themselves.

Cleaning turns out to be one of the basic prerogatives for the transformation and production of a high quality final product.